A groundbreaking thermal interface material (TIM) developed by researchers at the University of Texas Austin promises to transform cooling technology in data centers and beyond. This innovative material offers 72% better cooling performance compared to conventional thermal pastes, potentially reducing the need for power-hungry cooling systems.

A Cool Solution for Hot Data Centers

As data centers continue to expand and process increasing amounts of information, keeping servers from overheating has become a major challenge. The new TIM, created through a mechanochemically engineered combination of liquid metal alloy Galinstan and ceramic aluminum nitride, addresses this issue head-on.

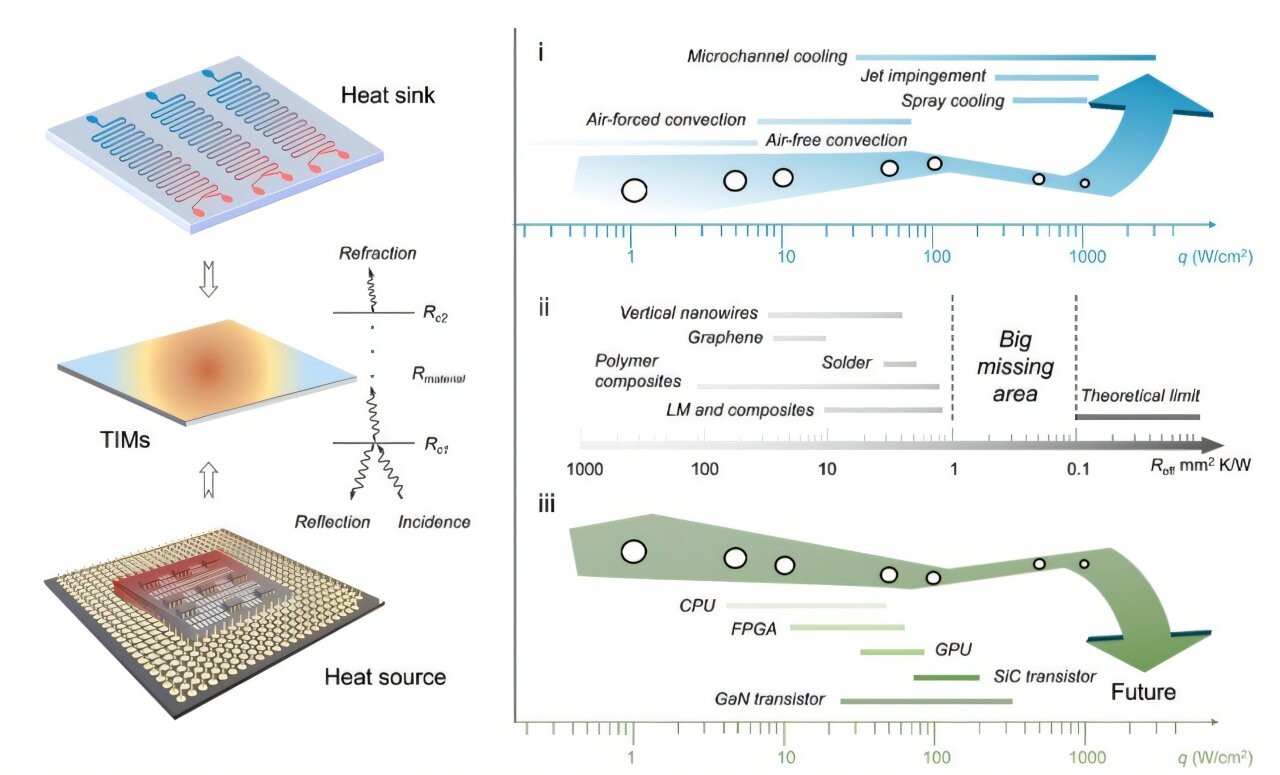

In laboratory tests, the material outperformed leading commercial liquid metal cooling products by an impressive 56-72%. It demonstrated the ability to dissipate up to 2,760 watts of heat from a mere 16 square centimeter area, showcasing its remarkable efficiency.

The Science Behind the Breakthrough

The exceptional performance of this new TIM stems from its unique composition and manufacturing process. By utilizing mechanochemistry, researchers were able to mix the liquid metal and ceramic ingredients with unprecedented precision. This resulted in gradient interfaces that allow heat to flow much more easily, bridging the gap between theoretical heat transfer limits and real-world applications.

Energy Savings and Environmental Impact

Beyond its superior cooling capabilities, the new material offers significant energy-saving potential. Researchers claim that its higher performance can reduce the energy required to run cooling pumps and fans by up to 65%. This efficiency gain could have a substantial impact on data center operations, which currently consume about 8 terawatt-hours per year on cooling alone – roughly 40% of their total energy usage.

The University of Texas team estimates that implementing this new TIM across the industry could cut cooling energy needs by 13% and overall data center energy consumption by at least 5%. Such reductions would translate to substantial cost savings and a significant decrease in carbon emissions.

Future Applications and Availability

While the material has shown promising results in small-scale laboratory tests, it has yet to be produced in larger quantities for real-world trials. The research team is currently working on scaling up production to conduct tests with data center partners.

As development progresses, it's likely that this innovative TIM will first be deployed in large-scale server farms before becoming available for consumer applications. However, its potential to revolutionize cooling technology across various sectors is undeniable.

The creation of this high-performance thermal interface material marks a significant step forward in addressing the growing energy demands of our increasingly digital world. As research continues, we may soon see more efficient and environmentally friendly cooling solutions in data centers and beyond.