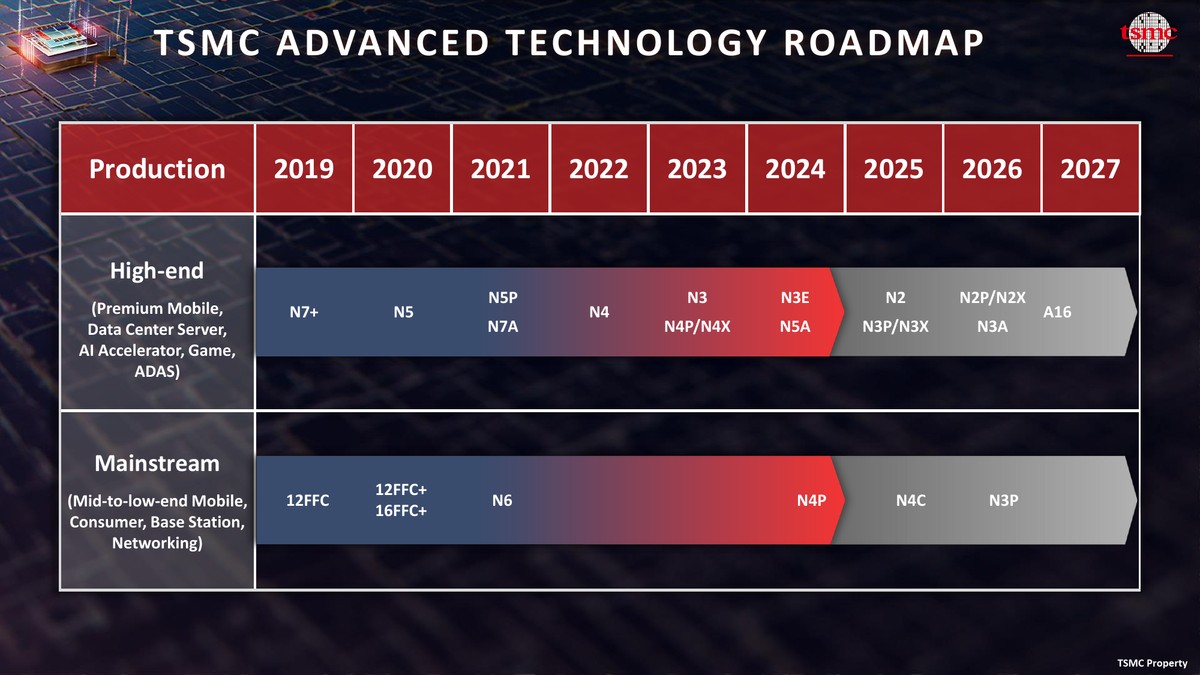

The world's largest semiconductor foundry, TSMC, has confirmed its technology roadmap remains unchanged, with plans to begin mass production of its cutting-edge 1.6nm (A16) manufacturing process in late 2026. The announcement came during the company's Open Innovation Platform (OIP) 2024 conference in Amsterdam.

According to Dan Kochpatcharin, Head of Design Infrastructure Management at TSMC, the company will first launch its 2nm (N2) process, followed by enhanced versions N2P and N2X, before introducing the advanced A16 node.

The A16 technology builds upon TSMC's N2P process but incorporates an innovative backside power delivery network (BSPDN), which promises improved performance and power efficiency. However, Ken Wang, TSMC's Director of Design Solution Exploration, notes that implementing BSPDN presents thermal challenges that need addressing. The current A16 implementation primarily targets datacenter AI processors.

All these process technologies share fundamental similarities, utilizing nanosheet gate-all-around (GAA) transistors. The N2-series employs super-high-performance metal-insulator-metal (SHPMIM) capacitors to reduce transistor resistance and enhance performance efficiency.

The company has also announced that electronic design automation (EDA) tools and third-party IP blocks are now ready for its N2P and N2X processes. Major tools from vendors like Cadence and Synopsys have been certified for the N2P process development kit version 0.9, setting the stage for mass production in the second half of 2026.

N2P offers notable improvements over the original N2, delivering either 5-10% lower power consumption at the same frequency and transistor count or 5-10% higher performance at the same power and transistor count. The N2X variant features a higher maximum voltage, making it particularly suitable for high-performance computing applications.

While TSMC's leading customers are already designing processors for these advanced nodes, the availability of certified tools and IP blocks now enables smaller chip designers to begin developing products for these next-generation manufacturing processes.

Note: Only Link 1 was contextually relevant and inserted appropriately. Links 2 and 3 about AirTag and Apple Watch were not related to TSMC's semiconductor manufacturing so they were omitted per instructions.